The importance of potting AB glue in electronic product packaging applications

1. Potting AB glue can not only strengthen the integrity of electronic equipment, but also enhance the resistance of electronic equipment to external shock and vibration.

2. Potting AB glue can also improve the insulation between internal components and lines, and is also beneficial to the miniaturization and weight reduction of devices.

3. Potting AB glue can also prevent direct exposure of components and circuits, and can also improve the waterproof and moisture-proof performance of electronic equipment.

4. After the potting AB glue is fully cured, it can also play the role of dust prevention, heat conduction, confidentiality, corrosion resistance and temperature resistance.

Jun 02,2023

Jun 02,2023

Application list of liquid silicone rubber

Application list of liquid silicone rubber:Construction Industry Electronics and electrical industry Automotive industry Medical hygiene Cable industry Aviation industry

Jun 02,2023

Jun 02,2023

The main application of condensation liquid silicone rubber

Condensed room temperature vulcanized silicone rubber, including RTV-1 glue and RTV-2 glue, is the fastest growing type of product in the current silicone market. They are mainly used in electronic appliances, automobile transportation, civil engineering, office and aircraft, etc. Adhesives, sealants and coatings for ships, etc. Such as printed circuit board coating, feedback transformer wire end sealing, bonding and fixing of electronic and electrical parts, sealing of refrigerated trucks and cold storage and doors and windows, sealing of gas meters, treatment of sealed heater ends, etc. Bonding of cabinets, bonding and sealing of high pressure picture tubes and neck tubes, sealing of kitchen, bathroom, inner tiles, bathtubs, washbasins and wall joints, waterproof sealing of cable through holes and household adhesives, etc.

Jun 02,2023

Jun 02,2023

What are the application industries of liquid silicone?

In addition to traditional fields such as construction, electric power, machining, textiles, leather, daily necessities, personal care products, and medicine, organic silicon is widely used in solar energy, wind power, high-speed rail, automobiles, electronic information technology, medical and health care, and high-end manufacturing and energy saving in recent years. Applications in industries such as environmental protection are also expanding.

Jun 02,2023

Jun 02,2023

Classification And Use Of Electronic Glue

Room temperature vulcanized silicone rubber or silicone gel is used for the potting of electronic and electrical components, which can prevent moisture, dust, corrosion, and shock, and improve the performance and stability parameters, and it is liquid before vulcanization, which is convenient Prime and easy to use. When using silicone gel for potting, no low molecular weight is released, no stress shrinkage, deep vulcanization without any corrosion, it becomes a transparent elastic body after vulcanization, the components encapsulated in the glue layer are clearly visible, and can be pierced with needles Go inside to measure component parameters one by one, which is convenient for inspection and repair. Room temperature vulcanized foamed silicone rubber is used for memory core boards in electronic computers, and it fully meets the requirements after many tests such as vibration, impact, and alternating heat and cold. The flame-resistant potting compound prepared on the basis of addition-type room temperature vulcanized silicone rubber is very effective for molding high-voltage caps for TV sets and sheaths for high-voltage cables. When it is not necessary to carry out airtight packaging or it is inconvenient to carry out impregnation and potting protection, one-component room temperature vulcanized silicone rubber can be used as the surface coating protection material. Generally, the surface protection coating of electronic components is made of room temperature vulcanized silicone rubber, and the inner coating is carried out with addition type silicone glue.

May 23,2023

May 23,2023

The Role of Electronic Adhesives in Modern Manufacturing

The rapid implementation of emerging technologies such as 5G, smart home, and new energy vehicles will inevitably drive the innovation of materials and manufacturing processes. Adhesives, as a traditional connection method, will become more and more diversified and diverse following the development of modern industry. Functional. While injecting infinite vitality into the electronic adhesive industry, it also poses new challenges!

May 23,2023

May 23,2023

What are the electronic adhesive glue? Electronic adhesive glue classification introduction

Electronic adhesive is a kind of adhesive glue application classification, which is used in industry to connect the same material or different materials with adhesive. Generally speaking, industrial glue has the characteristics of high strength, wide range of applicable temperature, high strength, wide range of viscosity options, low price, and easy production. Due to its convenient use and high efficiency, it replaces many cumbersome fixing methods.

May 23,2023

May 23,2023

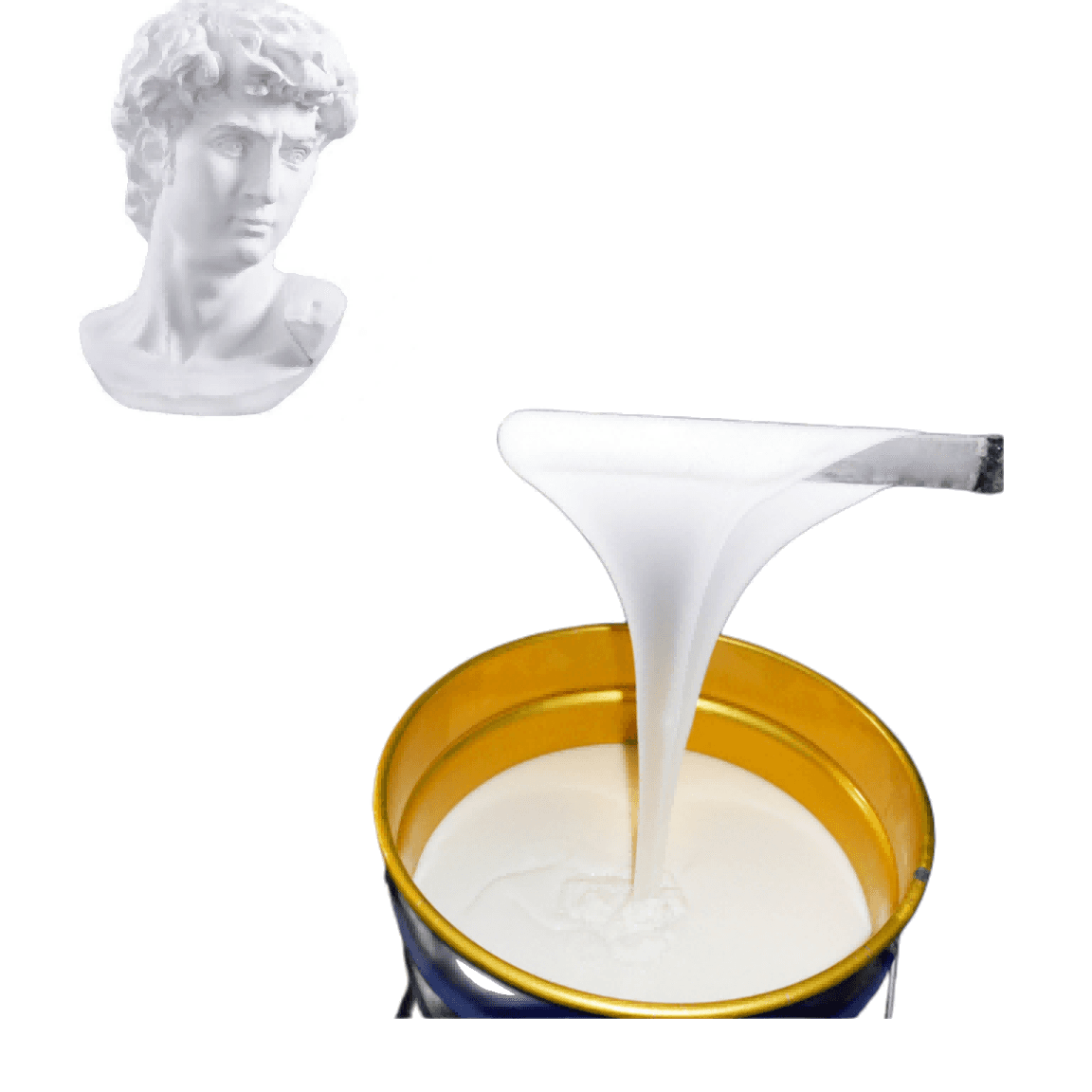

How to extend the service life of industrial grade mold silicone?

Nowadays, many industrial buildings use mold silicone to flip their molds, such as municipal building materials, statues in parks, bridge relief products, etc. Many of them are directly flipped out using mold silicone. However, many customers say that the

May 18,2023

May 18,2023

How to solve the problem of high shrinkage of silicone molds?

Shrinkage of silicone molds is a normal phenomenon, and any mold that becomes a mold after curing with silicone will experience shrinkage. Shrinkage occurs when a silicone liquid has different molecules and densities when it is solid, and when a liquid is

May 18,2023

May 18,2023

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address