What is the difference between platinum curing agent and common curing agent on the market

With the growing market, a variety of vulcanizing agents have appeared, and silica gel has also extended from the single molding requirements to more different requirements. The common vulcanization

If the agent can not meet the requirements, what should we do about this silica gel with special requirements? A special curing agent - platinum curing agent was born.

Jan 06,2023

Jan 06,2023

RTV | Characteristics and uses of silicone gel and its difference from silicone rubber

Silicon gel is also one of the types of silica gel. It is mainly liquid formed and can reach - 40 degrees of flexibility, and has high purity and strong elasticity. It belongs to semi solidified state after forming and curing. As

Jan 04,2023

Jan 04,2023

Application of RTV room temperature curing silicone rubber and neutral silicone sealant

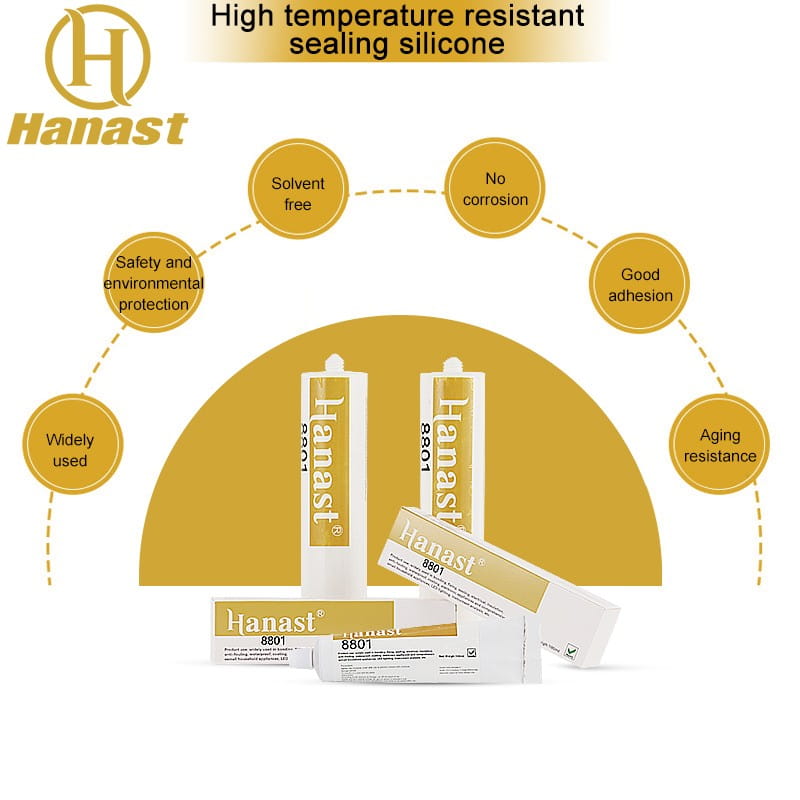

What is room temperature curing silicone rubber? We often see that no matter it is the same as a small toothpaste tube or a 300ml industrial silicone adhesive for a PE tube, there are many sealants with RTV silicone sealant marked on the outer package without exception. In fact, this RTV is common both at home and abroad. RTV is the abbreviation of "room temperature curing" in English, so room temperature curing silicone rubber is often referred to as RTV silicone rubber or silicone rubber.

Jan 03,2023

Jan 03,2023

Differences between RTV adhesive and epoxy resin adhesive (EP adhesive)

As a bonding, sealing, insulating, moisture-proof and shockproof material, RTV rubber (room temperature vulcanized silicone rubber) is widely used for bonding and sealing of electronic components, semiconductor materials, electronic appliances and other equipment, waterproofing and sealing of electric heaters and electronic instruments, and potting of electronic components. Such as sealing of electric heating end, bonding of small motor magnetic tile and metal shell, bonding and sealing of automobile lamps, optical instruments and lenses, bonding of electronic instrument shell, insulation protection of motor, bonding and sealing of electronic components, etc

Dec 30,2022

Dec 30,2022

What glue is used to stick LED sealant to the aluminum shell of LED lamp

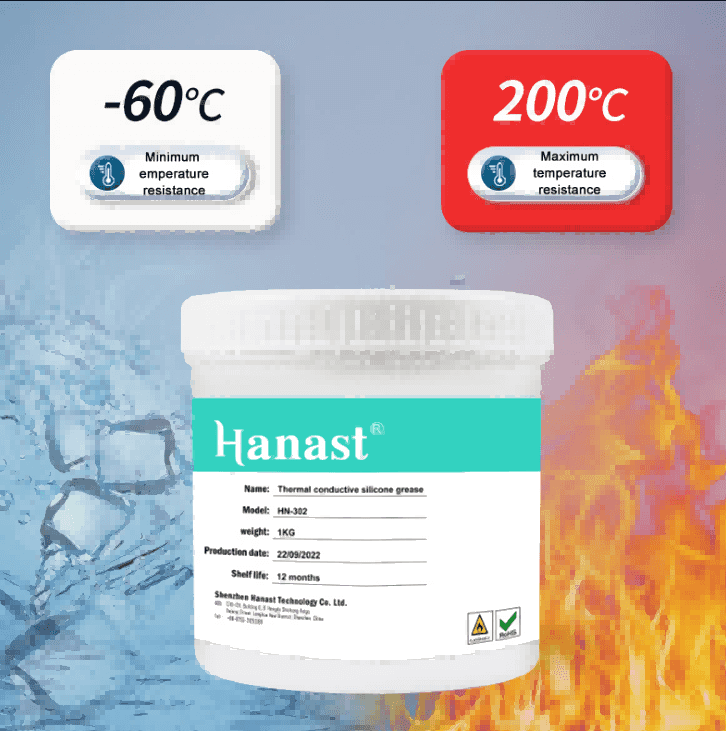

LED is a new material for energy-saving lamps. Plastic and aluminum shells are often used to protect LED lights. What kind of glue should be used for the aluminum shell of LED lamp? Everyone knows that charged products need good insulation, high temperature resistance, waterproof and sealing performance. Through laboratory testing, KN-300 LED sealant has excellent insulation performance, high temperature resistance of - 60 ℃ to 200 ℃, and protection grade of IP65.

Dec 29,2022

Dec 29,2022

Common problems and solutions in dispensing process of RTV waterproof sealant

This is caused by the shortening of RTV silicone waterproof sealing dispensing after processing and curing. Most of the problems are caused by the addition of solvent silicone resin to the adhesive, which is caused by the quality of RTV silicone itself.

Dec 28,2022

Dec 28,2022

Is silicone glue poisonous? What are the ingredients? Principle analysis and mechanism introduction of silica gel glue

Silica gel, also known as silicic acid gel, is a highly active adsorption material and an amorphous substance. Silicone consists of silicone based adhesive, silicon dioxide, calcium carbonate, curing agent, etc. The main component is silicon dioxide, which is chemically stable and does not burn. Silica gel can be said to play a more and more important role in our life, but in our daily use of silica gel, we are faced with the adhesion of silica gel and silica gel, silica gel and plastic products, silica gel and metal and other materials, which requires us to have the adhesive, that is, silica gel glue.

Dec 27,2022

Dec 27,2022

What are the common functions of the silicone glue bonding technology?

The components bonded with silica gel glue are smooth and lubricated in appearance, and their functional characteristics do not decline. For example, the use of adhesives for aerospace assembly eliminates negative loads, increases the payload, improves the voyage, and reduces the freight.

Dec 26,2022

Dec 26,2022

What is the difference between glue for sticking silica gel and glass glue?

Differences between glass adhesive and silica gel

Dec 23,2022

Dec 23,2022

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address