Solution for Bubble Content in Flipped Silicone Products

Situation description: When using flip mold silicone, if bubbles appear inside or on the surface of the silicone product after solidification, what is the reason for the occurrence of bubbles and the solution?

Situation analysis:

① The main reason

Mar 08,2024

Mar 08,2024

How to choose the appropriate hardness for liquid silicone

When the hardness of the mold silicone is below 10 hardness, the silicone tear strength is low, the elongation is high, and the silicone product is prone to deformation; When the hardness is higher than 50 hardness, the tear strength deteriorates, and sil

Mar 08,2024

Mar 08,2024

How to store liquid silicone gel

Properly storing liquid silicone can ensure that the material quality of silicone remains unchanged, thereby improving its service life and accuracy. The storage of silicone mainly involves the following aspects:

1、 Storage sealing. Due to the high sen

Mar 08,2024

Mar 08,2024

What is the reason for the powdery precipitation of electronic sealing adhesive

For users who are new to using silicone electronic potting adhesive, they may find a layer of powdery precipitate at the bottom of the purchased adhesive bucket. Therefore, they may suspect that there is a problem with the adhesive and whether it will aff

Mar 07,2024

Mar 07,2024

How many times can silicone flipping molds be used

Silicone flip mold (also known as silicone replica) refers to the use of a prototype to create a silicone mold in a vacuum state, and pouring it in a vacuum state using materials such as ABS, transparent PC, silicone, soft rubber, etc., to clone a replica

Mar 07,2024

Mar 07,2024

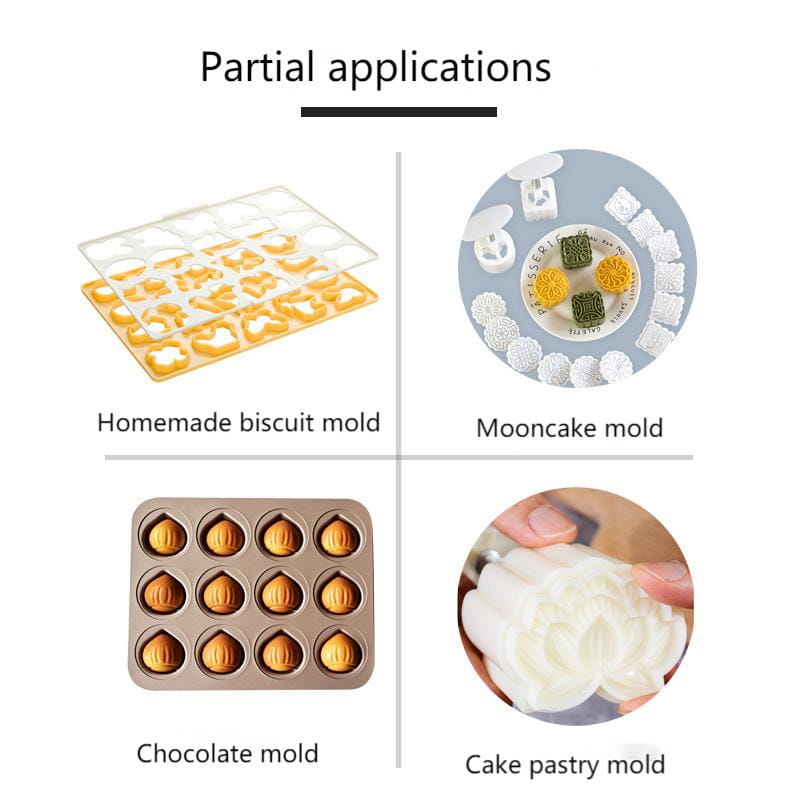

How to handle silicone mold sticking?

Silicone molds can be used for mass production of cement, gypsum, cultural stones, candles, soap, resin, food, prosthetics, human skin masks, models, and other products. During the production process, both mold opening and production must undergo a demold

Mar 07,2024

Mar 07,2024

Why does mold silicone appear to be dry on the surface but not on the inside

As is well known, mold silicone belongs to the Condensed liquid silicone, which is equivalent to an adsorbent that solidifies by absorbing moisture from the air. During the production process of silicone, if the water is evaporated without adding an appro

Mar 07,2024

Mar 07,2024

What precautions can prolong the usage rate of silicone molds

Mold silicone is divided into three, six, and nine grades, with high, medium, and low quality; Different quality grades of silicone molds are used, and the silicone molds produced are also classified into high, medium, and low. Here, I have to remind ever

Mar 07,2024

Mar 07,2024

Methods for reducing the shrinkage rate of silicone gel

The serious shrinkage of silicone is mainly due to the quality problem of the silicone itself. If the quality is not up to standard, it is normal for the shrinkage rate of the flipped silicone extracted with powder or waste rubber to be serious. liquid si

Mar 07,2024

Mar 07,2024

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address